How to become an Instrumentation & Control

Overview, Courses, Exam, Colleges, Pathways, Salary

Overview

Who is Instrumentation & Control ?

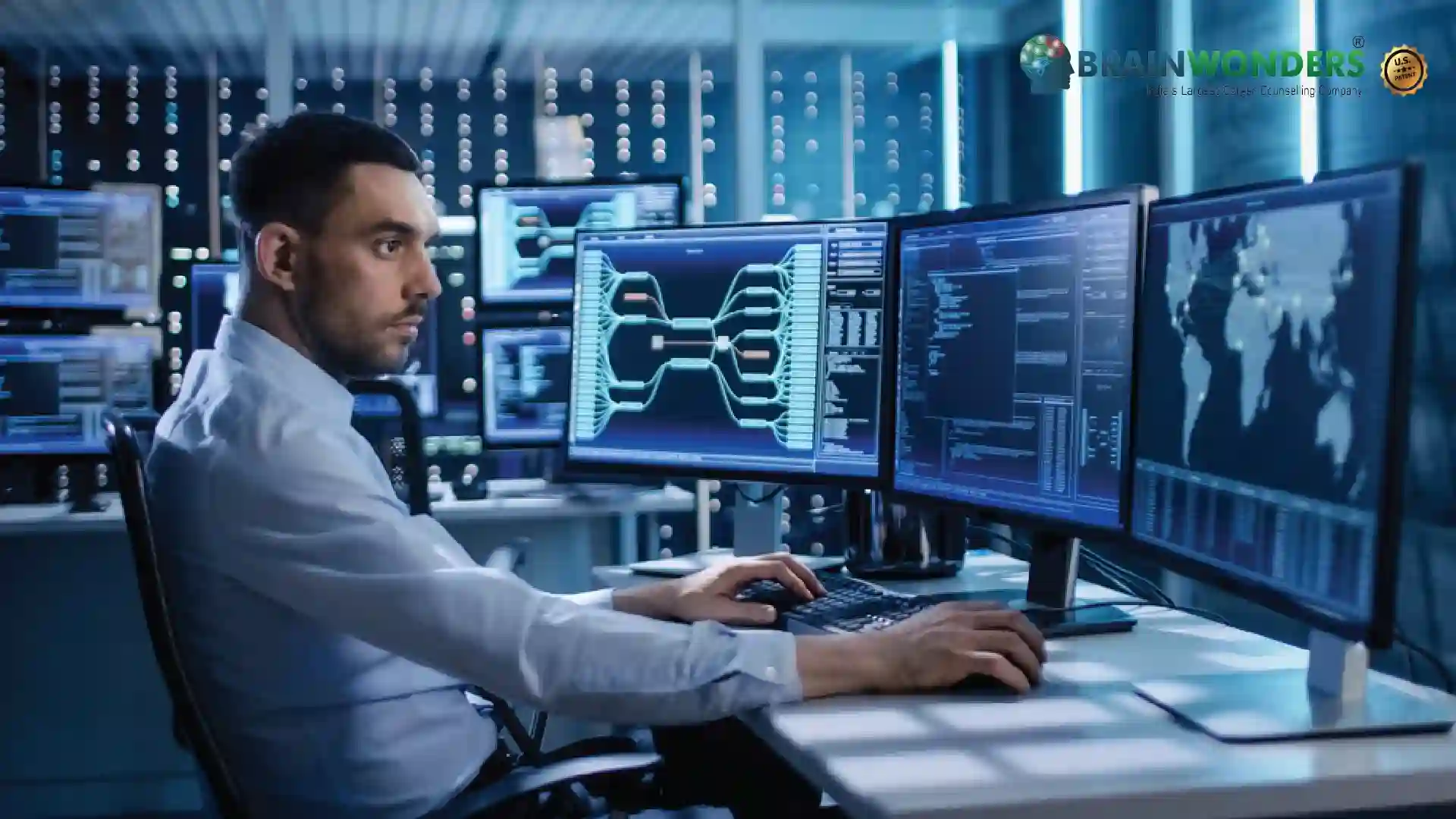

An Instrumentation & Control professional specializes in designing, implementing, and maintaining systems that measure and regulate various parameters in industrial processes. These experts ensure accurate monitoring and efficient control of temperature, pressure, flow, etc. They play a vital role in manufacturing, energy, automation, and chemical processing, where precise control is crucial for safety, quality, and efficiency. Instrumentation and control professionals work with sensors, transmitters, PLCs, DCS, and other advanced technologies to develop systems that optimize processes, detect abnormalities, and provide real-time data for decision-making. Their expertise improves operational performance, reduces risks, and enhances productivity across various industries.

Typical day at work

What does Instrumentation & Control do?

An Instrumentation and control professional is responsible for designing, implementing, and maintaining systems that monitor and regulate various parameters in industrial processes to ensure efficient and safe operations. Here's what they do:

- System Design: They design instrumentation and control systems that include sensors, transmitters, actuators, controllers, and other devices to measure and control parameters like temperature, pressure, flow, and level.

- Sensor Selection: They choose appropriate sensors and measurement devices based on the specific requirements of the process or system being monitored.

- Instrument Calibration: Instrumentation and control professionals calibrate sensors and devices to ensure accurate and reliable measurements.

- Data Collection: They set up systems to collect real-time data from sensors and instruments, providing insights into process performance.

- Control Algorithms: They develop control algorithms that enable automated adjustments based on the collected data, ensuring optimal process conditions.

- Programming and Configuration: Instrumentation and control experts program and configure devices such as PLCs, DCS, and SCADA systems to implement control strategies.

- Safety Measures: They integrate safety protocols and emergency shutdown systems to prevent accidents and protect personnel and equipment.

- Troubleshooting: When issues arise, they troubleshoot and diagnose problems in the instrumentation and control systems to ensure minimal downtime.

- Maintenance: Regular maintenance of instruments and control systems is essential, and these professionals perform maintenance tasks to keep systems operational.

- Process Optimization: They analyze data to identify areas for process improvement, aiming to enhance efficiency, reduce waste, and minimize energy consumption.

- Automation Implementation: Instrumentation and control experts play a key role in automating industrial processes, leading to improved consistency and reduced human intervention.

- Quality Control: They ensure that product quality and process parameters meet industry standards and regulations through monitoring and adjustments.

- Integration: They integrate instrumentation and control systems with other components of a larger industrial process, creating a seamless operation.

- Documentation: Maintaining accurate records and documentation of system configurations, changes, and maintenance activities is vital.

- Training: They train operators and maintenance staff on properly using, maintaining, and troubleshooting instrumentation and control systems.

- Regulatory Compliance: Instrumentation and control professionals ensure systems adhere to industry regulations and safety standards.

Abilities and Aptitude needed

What are the skills, abilities & aptitude needed to become Instrumentation & Control?

Becoming proficient in Instrumentation & Control requires a combination of technical abilities, skills, and specific aptitudes. Here's what you need to develop to excel in this field:

Abilities:

- Analytical Thinking: Understanding complex systems and analyzing data to identify issues, optimize processes, and improve efficiency.

- Problem-Solving: Addressing technical challenges, diagnosing faults, and developing innovative solutions to ensure optimal system performance.

- Attention to Detail: Precision in designing, installing, and calibrating instruments to ensure accurate measurements and controls.

- Logical Reasoning: Applying logical thinking to troubleshoot and diagnose issues in instrumentation and control systems.

Skills:

- Technical Proficiency: Mastery of various instruments, sensors, actuators, PLCs, SCADA systems, and other relevant technologies.

- Programming Skills: Proficiency in programming languages such as ladder logic, structured text, or scripting languages for configuring PLCs and control systems.

- Data Analysis: Ability to analyze data collected from instruments and control systems to optimize processes and make informed decisions.

- Electrical and Electronics Knowledge: Understanding electrical circuits, signals, and electronic components used in instrumentation systems.

- System Integration: Skills to integrate various control system components and ensure seamless communication between devices.

- Safety Awareness: Knowledge of safety protocols and procedures to design systems that prioritize the safety of personnel and equipment.

Aptitudes:

- Curiosity and Learning: The field continuously evolves, so a desire to learn about new technologies and stay updated is crucial.

- Attention Management: The ability to handle multiple tasks and components simultaneously, ensuring everything is noticed.

- Detail Orientation: Meticulous in calibrations, measurements, and programming to achieve accurate and reliable results.

- Technical Curiosity: A genuine interest in understanding how instruments and control systems work and a willingness to explore new technologies.

- Adaptability: Given the dynamic nature of the field, being open to learning and adapting to new tools, techniques, and technologies is essential.

- Communication: Effectively conveying technical information to colleagues, clients, and non-technical stakeholders.

- Patience: Troubleshooting and resolving complex technical issues may require patience and persistence.

Salary

Salary for Instrumentation & Control?

The salary of An Instrumentation & Control is as follows :

- Minimum Monthly Salary: Entry-level Instrumentation and control Engineers or those in junior positions can expect a monthly salary ranging from INR 25,000 to INR 50,000. This salary range is typical for individuals beginning their instrumentation and control engineering careers.

- Maximum Monthly Salary: Experienced and highly skilled Instrumentation and control Engineers, especially those working with reputable engineering firms or specializing in complex automation and control systems, have the potential to earn a monthly salary ranging from INR 1,20,000 to INR 2,50,000 or even more.

- Annual Salary: The annual salary of an Instrumentation & Control Engineer can vary significantly, ranging from INR 3,00,000 to several lakhs or more. This range is influenced by years of experience, expertise in specific industries (such as oil and gas, manufacturing, or process control), and proficiency in advanced control technologies.

- Highest Position and Scope: The pinnacle of achievement for Instrumentation and control Engineers often comes when they attain senior engineering positions, lead control system design teams, or contribute to innovative automation projects. Accomplished Instrumentation and control Engineers with a deep understanding of measurement and control principles, strong problem-solving skills, and a proven track record of successful automation projects can command significant recognition and compensation. The scope for Instrumentation and control Engineers is promising, driven by the increasing demand for automation and smart control systems across industries. As technology advances, processes become more sophisticated, and the need for precise control and monitoring grows, Instrumentation and control Engineers play a vital role in designing, implementing, and maintaining control systems that enhance efficiency, safety, and productivity in various sectors.

Pathways

How to become an Instrumentation & Control?

Entrance Exam

Entrance Exam for Instrumentation & Control ?

Courses

Which course I can pursue?

Best Colleges

Which are the best colleges to attend to become an Instrumentation & Control?

Industries

Which Industries are open for Instrumentation & Control?

Instrumentation and control professionals have a wide range of industries to choose from, as their expertise is critical in ensuring efficient and precise monitoring and regulation of industrial processes. Here are some sectors that offer opportunities for Instrumentation & Control specialists:

- Manufacturing: Industries like automotive, electronics, food and beverage, and pharmaceuticals rely on instrumentation and control systems for process optimization, quality control, and automation.

- Energy and Utilities: Power generation, distribution, and renewable energy sectors require experts to design and maintain control systems for efficient energy production and management.

- Oil and Gas: The oil and gas industry uses instrumentation and control systems for monitoring and controlling drilling operations, refining processes, and pipeline transportation.

- Chemical Processing: Chemical plants use control systems to manage complex chemical reactions, ensuring safety and product consistency.

- Aerospace and Defense: In this sector, professionals work on avionics, flight control systems, navigation systems, and developing drones and uncrewed vehicles.

- Environmental Monitoring: Monitoring air quality, water quality, pollution levels, and other ecological parameters requires sophisticated instrumentation and control systems.

- Healthcare and Medical Devices: Medical equipment, patient monitoring systems, and laboratory instruments rely on precise control and measurement technologies.

- Automotive Industry: The automotive sector employs instrumentation and control experts for vehicle performance and safety, from engine control units to diagnostics.

- Water and Wastewater Management: Water treatment plants and wastewater facilities use control systems to manage processes and ensure water quality.

- Telecommunications: Network monitoring, data centres, and communication infrastructure rely on control systems for efficient operation and troubleshooting.

- Building Automation: Building management systems control lighting, HVAC, security, and energy consumption in commercial and residential structures.

- Renewable Energy: Solar, wind, hydroelectric, and other renewable energy systems require control and monitoring for efficient energy generation.

- Research and Development: Research institutions and laboratories employ experts to develop innovative instrumentation and measurement solutions.

- Pharmaceutical Industry: Ensuring consistent manufacturing processes and complying with regulatory standards relies on accurate control systems.

- Food Processing: The food and beverage industry uses control systems for production, packaging, and quality control.

- Mining and Minerals: Instrumentation and control systems are used in mining operations to monitor and control processes and equipment.

- Smart Cities and Infrastructure: Developing and implementing control systems for urban infrastructure and smart city projects.

- Transportation: Railway systems, airports, and public transportation networks require control systems for safety and efficiency.

internship

Are there internships available for Instrumentation & Control?

Here are potential internship opportunities for individuals interested in pursuing a career in Instrumentation & Control:

- Manufacturing Companies: Industries like manufacturing hire interns for process automation, quality control, and data analysis using instrumentation and control systems.

- Energy and Utilities: Companies in the energy sector offer internships in areas such as power plant control systems, renewable energy integration, and smart grid technologies.

- Oil and Gas Industry: Interning with oil and gas companies involves working on instrumentation for monitoring pipelines, refineries, and offshore platforms.

- Chemical Processing: Chemical companies offer internships designing and optimizing control systems for chemical processes and safety protocols.

- Automation and Robotics Firms: Internships in this sector focus on designing control algorithms, programming PLCs, and working with robotic systems.

- Aerospace and Defense: Internships in aerospace companies involve working on avionics and control systems for aircraft, spacecraft, and drones.

- Pharmaceutical Industry: Pharmaceutical companies offer internships in process control for manufacturing medications and maintaining quality standards.

- Environmental Monitoring: Organizations focused on ecological monitoring offer internships in designing systems to measure pollution, air quality, and water parameters.

- Research and Development Centers: Research institutions provide internships involving cutting-edge instrumentation, sensors, and data analysis projects.

- Automotive Industry: Interning with automotive companies involves working on control systems for vehicles, autonomous driving, and vehicle diagnostics.

- Water and Wastewater Management: Internships in this sector focus on control systems for water treatment plants and wastewater management.

- Building Automation: Facilities management companies offer internships in building automation systems for controlling lighting, HVAC, and energy consumption.

- Healthcare and Medical Devices: Internships involve working on medical devices, patient monitoring systems, and control systems in healthcare settings.

- Telecommunications and Networking: Internships in this sector include working on control systems for telecommunications networks and data centres.

- Smart Cities and Infrastructure: Organizations working on smart city projects offer internships involving control systems for urban infrastructure.

- Renewable Energy Industry: Internships in this sector focus on control systems for solar, wind, and other renewable energy sources.

Career outlook

What does the future look like for Instrumentation & Control?

The future for Instrumentation and control professionals is promising as industries continue to rely on advanced technologies for efficient and safe operations. With the rise of automation, Industry 4.0, and the Internet of Things (IoT), the demand for experts in instrumentation, process control, and automation is expected to grow. These professionals will be pivotal in designing and implementing systems that optimize processes, enhance data collection, and enable remote monitoring. Manufacturing, energy, pharmaceuticals, and automation sectors will offer ample opportunities. Integrating AI and machine learning into control systems will redefine the role, requiring professionals to adapt to these advancements. Continuous learning, staying updated with emerging technologies, and adapting to industry changes will be key. Overall, Instrumentation and control specialists are poised to play a critical role in shaping the future of industries through innovative automation and data-driven solutions.