How to become a Metallurgical Engineer

Overview, Courses, Exam, Colleges, Pathways, Salary

Overview

Who is Metallurgical Engineer ?

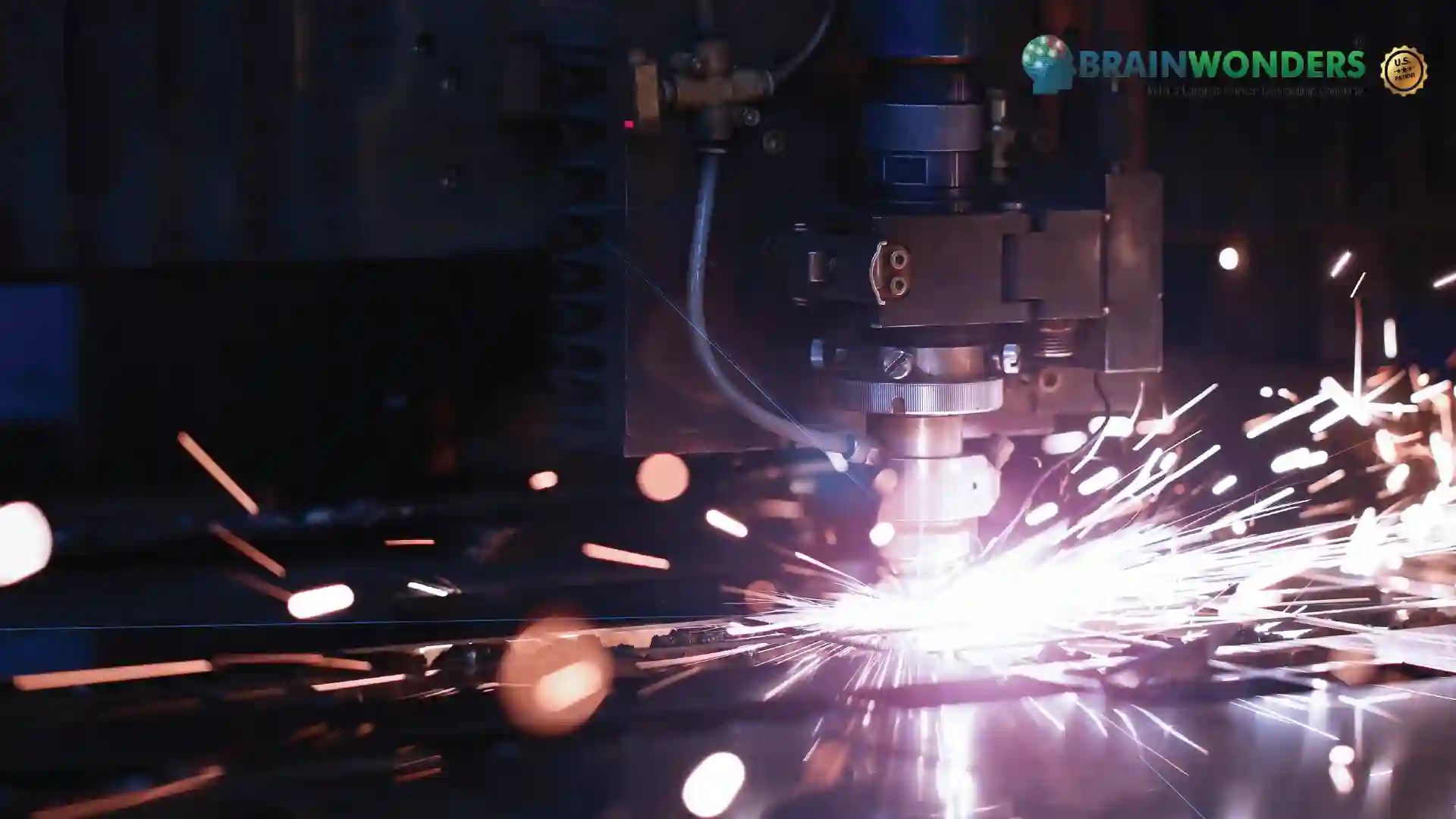

Metallurgy is the discipline of science and engineering that examines the physical and chemical behaviour of metallic elements, intermetallic compounds, and alloys, which are mixes of metallic components. Metallurgy involves both metal science and metal technology. Metallurgical engineering is a branch of engineering that deals with metals and alloys in various industrial and manufacturing contexts. Material engineering is a sub-branch of metallurgical engineering. A Metallurgist, also known as Material Science Engineer or Metallurgical Engineer, is a mineral expert specialising in the processes for the extraction of metals from their ores. They employ their knowledge of metals, their elements, chemical behaviour, compounds, alloys, and methods to generate metallic materials used to manufacture a wide range of goods. Metal and alloy analysts are primarily responsible for determining metals and alloys' physical and chemical characteristics.

Metallurgical engineers contribute to manufacturing and developing new alloys for specific applications, such as lightweight, solid metals for automobiles, aircraft parts or conductive metals for electronics. Material and metallurgical Engineering is a broad area that deals with creating and distributing all types of metal-related products. Metallurgy employs the concepts of chemistry, physics, and mathematics, as well as a grasp of metal manufacturing processes and material behaviour, to convert the earth's natural resources into finished products by extracting metals from ores, producing ceramics from metal compounds and fabricating composite structures, Metallurgical Engineering produces many exotic materials such as metals with shape memories, ceramics for space vehicles, ultrahigh-purity materials for integrated circuits, materials for surgical implants and superconductors.

Typical day at work

What does Metallurgical Engineer do?

Metallurgical engineers are responsible for producing materials, evaluating metals, ceramics, and polymer-based composites. In addition, the role of the Metallurgical Engineer is to develop processing methods to create materials.

- Design processes and use physical and chemical techniques to separate valuable minerals from ores and reducing minerals into metals and alloys

- Plants designed and operated for the production of concentrated mineral and metal products

- Oversee sampling at different processing stages for laboratory analysis and testing

- Developing and supervising environmentally friendly processes

- Test metals in operation, record data and direct on performance and limitations

- Study the radiation effects on metals exposed to space environment and nuclear reactors

- Change and improve recovery and quality processes, and reduce waste and costs

- Confer with other personnel about production methods and quality control systems to improve efficiencies

- Limit expenditure, develop budgets and draft technical reports

- Assess metal properties to establish the kind of metal to be used

- Conduct experiments in power metallurgy and the method of compressing and sintering metallic powders at high temperatures

- Research microscopic, x-ray, x-ray diffraction and spectrographic studies of metals and alloys

- Tests alloys for anticipated use to study engineering properties and confirm standard safety and quality compliance

- Produce alloys to reduce air pollution and to implement testing procedures at lowest cost.

- Develop hot-working and cooling processes to change the physical and chemical properties of metals to gain desired properties of being stronger or more adaptable

- Assess the effect of exotic or unusual metals

- Assess and monitor metal condition for corrosion, rupture or failure both at the site and in a laboratory environment

- Conduct destructive and non-destructive tests to evaluate the particular properties of metals like electrical conductivity, durability, renewability

- Measure resistance of metals to humidity, high temperatures, chemicals, etc.

- Refine molten metals in furnaces

- Make metal castings

- Analyse new product plans and provide suggestions for selection of material, based on design objectives like strength, weight, heat resistance, electrical conductivity, and cost

- Test raw materials or finished products to guarantee its quality

- Plan and implement laboratory operations to develop appropriate methods for fabricating and joining materials that meet cost, product specification, and performance standards

- Replicate the materials characteristics and components with computers.

- Meeting with clients to determine design requirements

- Provide technical advice about the suitability of metals

- Advice and make recommendation about product feasibility

- Undertake new product research and create designs for components

- Develop innovative solutions and prototypes to problems

- Investigate metal failure/fatigue and corrosion

Abilities and Aptitude needed

What are the skills, abilities & aptitude needed to become Metallurgical Engineer?

A metallurgist must be well-versed in metals, their practical uses, and the specific problems they provide. It is necessary to comprehend highly technical stuff such as raw data and scientific publications. They regularly use complex mathematical equations, statistics, and formulas in their work.

Since the work includes practical activity, hands-on problems and solutions, they should be comfortable working with materials, tools, and machinery. This requires manual skill, precision, an eye for detail, accuracy, and careful equipment monitoring. In addition, they must have physical stamina because they may be on their feet for extended periods. They should also be adaptable enough to function in a variety of settings. Finally, they must manage time properly and prioritise projects while maintaining job quality.

They tend to be investigative, intellectual, reflective, and curious individuals. In addition, they are curious, systematic, scientific, logical, rational, and analytical.

They should communicate effectively, both verbally and in writing, their research processes and findings. They usually work in or lead teams and must be able to motivate and direct other team members. Thus, interpersonal and project management skills are necessary.

They need critical thinking and problem-solving skills to find solutions to complex problems and draw conclusions from experimental results through sound reasoning and judgment.

Salary

Salary for Metallurgical Engineer?

Salary of a Metallurgical Engineer is as follows :

- Minimum Monthly Salary for Entry-Level Metallurgical Engineers: The initial salary for entry-level metallurgical engineers varies based on location, industry, and specialization. In India, newly graduated metallurgical engineers can anticipate a monthly salary ranging from approximately INR 25,000 to INR 35,000 as they embark on their careers. This foundational salary enables them to acquire practical experience and proficiency within the metallurgical field.

- Maximum Monthly Salary for Experienced Metallurgical Engineers: Experienced metallurgical engineers, especially those who have specialized training or are advanced in their roles, have the potential to earn higher monthly salaries. Their earnings could range from approximately INR 60,000 to INR 1,50,000 or more, reflecting their advanced skills, leadership responsibilities, and significant contributions to metallurgical research, development, and production.

- Annual Salary Range for Junior and Accomplished Metallurgical Engineers: Starting as junior metallurgical engineers, individuals might expect an annual salary ranging from approximately INR 3 lakhs to INR 5 lakhs. As they gain substantial experience, progress in their careers, and take on leadership roles, they can aspire to an annual income ranging from INR 6 lakhs to INR 12 lakhs or beyond. Accomplished metallurgical engineers, often with specialized training or expertise, can command higher salaries based on their roles and contributions.

- Highest-Paying Job Opportunities and Scope: Lucrative opportunities exist within various industries for metallurgical engineers, including manufacturing, aerospace, automotive, mining, and materials research. Those specializing in materials testing, quality control, advanced alloy development, and process optimization often have a higher earning potential. The scope of metallurgical careers is promising, as engineers play a vital role in developing new materials, enhancing existing processes, and ensuring the quality of metal-based products. With the increasing demand for technological advancements, sustainability, and innovative materials, skilled metallurgical engineers are expected to be in high demand. This growth offers substantial opportunities for career advancement, specialization, and strategic contributions within diverse industries.

Pathways

How to become an Metallurgical Engineer?

Entrance Exam

Entrance Exam for Metallurgical Engineer ?

To enroll into a Bachelor's Program in Metallurgical Engineer, it is essential for the aspiring candidate to clear entrance exams conducted by various educational institutes. Most widely conducted entrance exams are JEE / JEE MAIN.

Courses

Which course I can pursue?

Best Colleges

Which are the best colleges to attend to become an Metallurgical Engineer?

Industries

Which Industries are open for Metallurgical Engineer?

Metallurgical engineers have diverse career opportunities across various industries due to their expertise in understanding and manipulating the properties of metals and materials. Here are some industries where metallurgical engineers can find employment:

- Manufacturing Industry: Metallurgical engineers contribute to producing metal products, including steel, aluminium, and alloys, ensuring quality, durability, and performance.

- Aerospace and Aviation: Metallurgical engineers work on materials for aircraft, spacecraft, and components, focusing on lightweight yet solid materials for extreme conditions.

- Automotive Industry: Metallurgical engineers develop materials for automobile parts, improving safety, efficiency, and performance.

- Mining and Extraction: Metallurgical engineers extract and refine metals from ores, optimise extraction processes, and ensure resource efficiency.

- Energy and Power Generation: Metallurgical engineers contribute to materials used in power plants, turbines, and energy infrastructure to withstand high temperatures and harsh environments.

- Oil and Gas Industry: Metallurgical engineers work on corrosion-resistant materials for pipelines, equipment, and offshore structures.

- Research and Development: Metallurgical engineers engage in materials research, exploring new alloys, techniques, and applications.

- Defence and Military: Metallurgical engineers develop materials for military equipment, including armour, weaponry, and specialised vehicles.

- Biomedical and Medical Devices: Metallurgical engineers design biocompatible materials for medical implants, devices, and equipment.

- Environmental and Sustainable Practices: Metallurgical engineers focus on eco-friendly materials and processes, minimising environmental impact.

- Consulting and Technical Services: Metallurgical engineers specialise in material selection, analysis, and failure investigations.

- Nuclear Industry: Metallurgical engineers work on materials for nuclear reactors, ensuring safety and stability.

- Construction and Infrastructure: Metallurgical engineers contribute to strong and durable materials in construction and infrastructure projects.

- Jewellery and Art: Metallurgical engineers with specialised knowledge contribute to creating intricate jewellery and artistic pieces.

- Renewable Energy: Metallurgical engineers are involved in developing materials for renewable energy technologies, such as solar panels and wind turbines.

- Consumer Goods: Metallurgical engineers work on everyday items like kitchenware, appliances, and electronics.

- Semiconductor Industry: Metallurgical engineers contribute to materials used in semiconductor fabrication processes.

- Materials Testing Laboratories: Metallurgical engineers analyse and test materials for various industries.

internship

Are there internships available for Metallurgical Engineer?

Metallurgical engineering internships provide valuable hands-on experience for students and aspiring engineers to apply their knowledge in real-world settings. Here are some potential industries and organizations where internships for metallurgical engineers may be available:

- Manufacturing Companies: Industries in metal fabrication, aerospace, automotive, and consumer goods offer internships in materials testing, quality control, and production processes.

- Mining and Extraction Companies: Internships provide insights into ore processing, metallurgical testing, and refining processes for extracting metals from raw materials.

- Aerospace and Defense Industries: Interns work on developing and testing high-performance materials for aircraft, spacecraft, and military applications.

- Research Institutions and Laboratories: Universities, government labs, and private research institutions offer internships focused on cutting-edge materials science research.

- Energy and Power Generation Companies: Interns work with materials used in power plants, turbines, and energy infrastructure, focusing on performance under extreme conditions.

- Automotive Manufacturers: Internships involve materials selection, testing, and development for automotive components.

- Oil and Gas Companies: Interns may conduct corrosion testing, material selection for pipelines, and research new materials for harsh environments.

- Consulting Firms: Metallurgical engineering interns analyze materials, investigate failures, and provide recommendations to clients.

- Biomedical and Medical Device Companies: Interns work on biocompatible materials for medical implants and devices.

- Environmental and Sustainable Practices: Internships focus on sustainable materials and processes to minimize environmental impact.

- Metallurgical Testing Laboratories: Interns gain experience in testing and analyzing metal properties.

- Automotive and Aerospace Research Centers: Interns contribute to innovative projects in these industries.

- Materials Manufacturing Companies: Internships cover speciality materials like superalloys and advanced composites.

- Steel and Iron Foundries: Interns learn about casting and production processes.

Career outlook

What does the future look like for Metallurgical Engineer?

One may specialise in various metallurgical fields like chemical (involved in the extraction of metals from ores and studying metal corrosion), physical (monitor metals under stress and temperature), process (shape, join, and select best-fit metals), and Archaeological (study mining developments and excavation strategies, perform chemical tests on artefacts).

Metallurgists may work full-time in a laboratory setting, in-office setups, or fields. They may also work for the government, private agencies, or academic settings. There has been a demand for metallurgical engineers in India and abroad. The job provides a variety of opportunities and promises high monetary rewards. However, the field settings may be dangerous as one may have to work in a mine, oil and gas manufacturing plant and be exposed to high temperature, humidity, toxic chemicals, and other pollutants.