How to become a Structural Metal Fabricator and Fitter

Overview, Courses, Exam, Colleges, Pathways, Salary

Overview

Who is Structural Metal Fabricator and Fitter ?

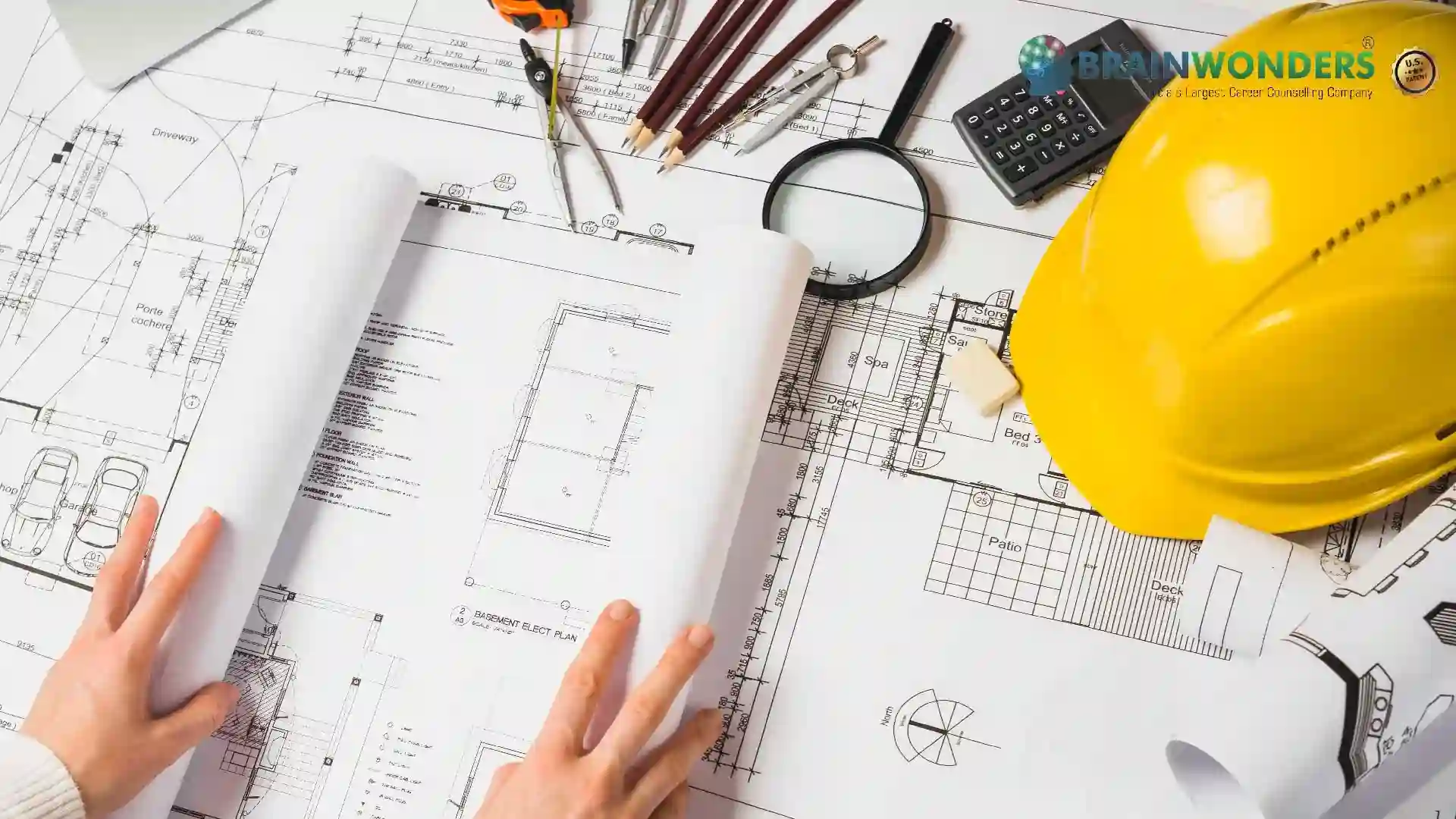

A Structural Metal Fabricator and Fitter is a skilled professional specializing in fabricating, assembling, and installing metal structures, such as beams, columns, and frameworks used in construction and manufacturing. They work with various types of metal, including steel and aluminum, and use specialized tools and techniques to shape, cut, weld, and fit metal components according to blueprints and specifications.

Structural Metal Fabricators and Fitters are responsible for interpreting engineering drawings, measuring and marking metal materials, and performing precision welding and fabrication processes. They operate shears, saws, drills, and welding equipment to shape and join metal pieces. They ensure the fabricated components are accurately aligned, leveled, and secured for installation. Attention to detail, manual dexterity, and a thorough understanding of metalworking techniques are essential for success in this role. They typically work in construction, manufacturing, or metal fabrication industries, contributing to the creation of safe and durable metal structures.

Typical day at work

What does Structural Metal Fabricator and Fitter do?

A Structural Metal Fabricator and Fitter performs various tasks related to fabricating, assembling, and installing metal structures. Some of the key responsibilities of a Structural Metal Fabricator and Fitter include:

- Reading and Interpreting Blueprints: They analyze engineering drawings, blueprints, and specifications to understand the requirements of the metal structure to be fabricated.

- Metal Preparation: They measure, mark, and cut metal materials, such as steel beams, columns, and plates, using tools such as saws, shears, and torches. They may also use computer-aided cutting machines for precision cutting.

- Welding and Fabrication: They perform various welding techniques, such as arc welding, MIG (Metal Inert Gas) welding, or TIG (Tungsten Inert Gas) welding, to combine metal components. They use specialized tools and equipment to shape and fabricate metal parts according to the specifications.

- Assembly and Fitting: They fit and align metal components, ensuring they are accurately positioned and securely fastened. It involves using hand and power tools to adjust and align the metal parts to meet the desired specifications.

- Quality Control: They inspect fabricated components for accuracy, quality, and adherence to specifications. They check for proper alignment, dimensions, and weld quality to ensure the structural integrity of the finished product.

- Equipment Maintenance: They clean, maintain, and perform routine inspections on tools, machinery, and welding equipment to ensure proper functioning and safety.

- Safety Compliance: They adhere to safety protocols and guidelines while working with metal and operating machinery. They wear appropriate protective gear and ensure a safe working environment.

- Collaboration: They may work closely with engineers, architects, and other construction professionals to ensure the fabricated metal structures meet project requirements.

Abilities and Aptitude needed

What are the skills, abilities & aptitude needed to become Structural Metal Fabricator and Fitter?

Several skills, abilities, and aptitudes are important to become a successful Structural Metal Fabricator and Fitter. These include:

- Metalworking Skills: Proficiency in metalworking techniques, such as cutting, shaping, and drilling, using tools and equipment like saws, shears, drills, and grinders.

- Welding Expertise: Knowledge and experience in various welding processes, including arc welding, MIG welding, TIG welding, and oxy-acetylene welding. The ability to produce strong and high-quality welds is crucial.

- Blueprint Reading: The ability to interpret and understand engineering drawings, blueprints, and specifications to fabricate and assemble metal structures accurately.

- Mathematical Skills: A solid foundation in mathematics is important for measuring and calculating dimensions, angles, and quantities of materials required for fabrication.

- Precision and Attention to Detail: The ability to work accurately and pay attention to detail is vital in ensuring precise measurements, alignments, and fit-ups of metal components.

- Manual Dexterity: Good hand-eye coordination, fine motor skills, and the ability to work with precision tools and equipment are necessary for handling and manipulating metal materials.

- Safety Awareness: A strong understanding of safety protocols and practices when working with metal, machinery, and welding equipment to ensure a safe working environment.

- Technical Knowledge: Familiarity with the different types of metals used in fabrication, their properties, and appropriate fabrication techniques for each type.

- Problem-Solving Skills: The ability to troubleshoot and find solutions to challenges that may arise during the fabrication and fitting process, such as alignment issues or material constraints.

- Physical Stamina: The role of a Structural Metal Fabricator and Fitter often involves physically demanding tasks, such as lifting heavy metal components and working in various positions. Good physical fitness and stamina are beneficial.

- Collaboration and Communication: The ability to work effectively as part of a team, communicate clearly with colleagues, and follow instructions from engineers, architects, and supervisors.

Salary

Salary for Structural Metal Fabricator and Fitter?

The salary for Structural Metal Fabricators and Fitters in India can expect a starting salary ranging from Rs.2,00,000 to Rs.4,00,000 per year. With experience and expertise, the salary range for mid-level professionals can extend to Rs.4,00,000 to Rs.8,00,000 per year.

Experienced professionals who have advanced skills, specialization in specific techniques, or work on large-scale projects may earn higher salaries. Senior-level Structural Metal Fabricators and Fitters with a significant amount of experience can potentially earn Rs.8,00,000 or more annually. It's important to note that these salary ranges are approximate and can vary depending on multiple factors. The highest paying job opportunities in this field are typically found in industries such as construction, manufacturing, engineering, and infrastructure development. Working on prestigious projects, being employed by reputed companies, or being involved in specialized areas of structural metal fabrication can potentially lead to higher salaries.

Pathways

How to become an Structural Metal Fabricator and Fitter?

Entrance Exam

Entrance Exam for Structural Metal Fabricator and Fitter ?

Courses

Which course I can pursue?

Best Colleges

Which are the best colleges to attend to become an Structural Metal Fabricator and Fitter?

Industries

Which Industries are open for Structural Metal Fabricator and Fitter?

Structural Metal Fabricators and Fitters can find employment in various industries that require the fabrication and installation of metal structures. Some of the industries that commonly employ Structural Metal Fabricators and Fitters include:

- Construction: The construction industry is a primary sector where Structural Metal Fabricators and Fitters are in demand. They work on projects such as buildings, bridges, stadiums, and infrastructure development.

- Manufacturing: Structural Metal Fabricators and Fitters are employed in manufacturing industries that produce metal structures and equipment, including industrial machinery, agricultural machinery, and transportation equipment.

- Metal Fabrication and Welding Shops: Many specialized metal fabrication and welding shops hire Structural Metal Fabricators and Fitters to fabricate and assemble custom metal structures according to client specifications.

- Shipbuilding and Marine Industries: Structural Metal Fabricators and Fitters are involved in the construction and repair of ships, boats, offshore platforms, and other marine structures.

- Oil and Gas: They may work in the oil and gas industry, fabricating and fitting metal structures for drilling rigs, pipelines, refineries, and other facilities.

- Aerospace and Aviation: In the aerospace and aviation industries, Structural Metal Fabricators and Fitters are responsible for fabricating and assembling metal components for aircraft, including fuselages, wings, and landing gear.

- Renewable Energy: The renewable energy sector, particularly wind and solar energy, requires the fabrication and installation of metal structures for wind turbines, solar panels, and supporting infrastructure.

- Infrastructure and Engineering Services: Structural Metal Fabricators and Fitters may work for infrastructure development firms, engineering consulting companies, or public works departments involved in the construction and maintenance of roads, bridges, and utility structures.

- Metal Supply and Distribution: They may be employed by metal supply and distribution companies, assisting in fabricating and preparing metal materials for various industries.

internship

Are there internships available for Structural Metal Fabricator and Fitter?

While internships specifically tailored for Structural Metal Fabricators and Fitters may not be as common as in some other fields, opportunities for internships can still be found. These internships can provide valuable hands-on experience and allow individuals to learn and apply real-life skills. Here are a few avenues where internships for aspiring Structural Metal Fabricators and Fitters may be available:

- Metal Fabrication and Welding Shops: Some metal fabrication and welding shops may offer internships to individuals interested in pursuing a career as a Structural Metal Fabricator and Fitter. These internships can provide exposure to the fabrication process, welding techniques, and working with different types of metal.

- Construction Companies: Construction companies undertaking metal-based projects may offer internships that involve working alongside experienced Structural Metal Fabricators and Fitters. It can provide valuable exposure to construction sites, metal assembly, and fitting processes.

- Apprenticeship Programs: Apprenticeship programs combine on-the-job training with classroom instruction and can be a valuable way to gain hands-on experience as a Structural Metal Fabricator and Fitter. Trade organizations, unions, or vocational training institutes typically offer these programs.

- Manufacturing Facilities: Manufacturing companies producing metal structures and equipment may have internship opportunities. These internships can provide exposure to large-scale metal fabrication processes and assembly lines.

- Metalworking and Welding Training Centers: Some vocational training centers or technical schools that offer metalworking and welding programs may have internship components as part of their curriculum. These internships can provide practical experience in a controlled learning environment.

Career outlook

What does the future look like for Structural Metal Fabricator and Fitter?

The future for Structural Metal Fabricators and Fitters appears favourable, with steady demand expected in the coming years. These professionals are essential in the construction, manufacturing, and infrastructure industries, where their skills in fabricating and fitting metal components are crucial.

Factors driving the demand for Structural Metal Fabricators and Fitters include population growth, urbanization, and infrastructure development. The construction of buildings, bridges, industrial structures, and other projects requires skilled individuals who can accurately fabricate and assemble metal components.

Moreover, advancements in technology, such as computer-aided design (CAD) and computer numerical control (CNC) machining, have improved the precision and efficiency of metal fabrication processes. Familiarity with these technologies is becoming increasingly important for professionals in this field.

While automation and robotics have the potential to impact some aspects of metal fabrication, the need for skilled human labour remains significant. Structural Metal Fabricators and Fitters possess specialized knowledge and expertise that is difficult to replace with automation, particularly in complex and customized projects.

As the emphasis on sustainable construction practices continues to grow, professionals in this field may also benefit from opportunities related to green building and renewable energy projects.

To thrive in this career, individuals should consider obtaining relevant certifications, staying updated with advancements in metal fabrication technologies, and gaining experience with different types of metals and fabrication techniques.